Non-Woven Fabrics And Their Uses In Agriculture

Non-woven fabrics have been made since the beginning of the industry of petrochemicals. The first time they were used, they were because of their softness and bulk when used for packaging, covering, filling, and many other uses. The use of non-woven fabrics has expanded to encompass civil engineering, the environmental and agricultural engineering. Its existence is evident everywhere, with a particular emphasis on its early applications in the agricultural sector. Non-woven fabrics are similar to fabric made from short fibers and long fibers that are connected by chemical, heat or mechanical treatments. In general, non-woven materials are less durable and more resilient than woven materials. There are a variety of non-woven fabrics that are utilized in a variety of industries. Non-woven fabrics are less prone to production costs than woven fabric. The nonwoven fabric markets and the industries are growing and growing. See this agriculture non woven fabric manufacturer for advice.

Non-woven industry development is a product that emerged out of the petrochemical sector following the invention of plastic cloth (film). It is lighter than plastic cloth and offers better ventilation. It is commonly employed in medical and sanitary items like sanitary napkins, facial towels, and filters, etc., and was later designed and used in engineering. Non-woven fabric can be utilized in the production of vegetable products to shield against cold damage. Although non-woven materials have an entirely different manufacturing process than plastic films, the fundamental raw materials are identical. These include PVC (polyvinyl chloride), PET (polyethylene), EVA [Ethylene Vinyl Acetate copolymer], PVA (polyvinyl alcohol), etc. It is possible to make a thin plastic film out of traditional plastic by melting it and inflating. It is a continuous film. It can stretch indefinitely. The film is smooth and doesn't have pores. It is inert and completely blocks any exchange and movement of molecules. Artificial chemical fibers, created using the above listed raw materials have become the most popular item in the world of textiles. They are made into cloth through the traditional process of warp and weft weaving. Non-woven fabrics are made by combining fibers in the same plane at various angles, in all directions instead of using traditional warp and weft techniques. It's more durable than traditional woven fabric and is made of raw materials in just one day. It's less expensive than traditional weaving that involves drawing fibers into yarn and then weaving. Non-woven textiles have been extensively employed in the fashion industry in recent years. Since the last few years, thanks to advancements in material science and the development of production technology Non-woven fabrics are becoming more diverse and used more and more widely. You can find different products and materials all over your day-to-day life. Due to their lightweight and easy production, non-woven materials have gained demand in the field of farming. Follow this non woven weed fabric for recommendations.

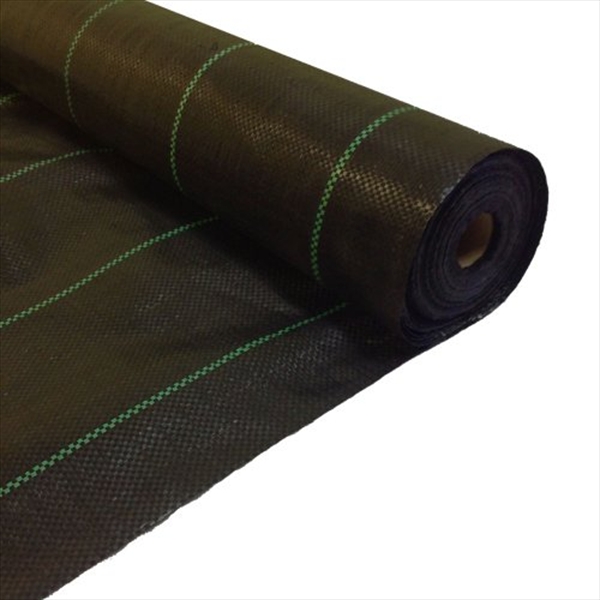

Non-Woven Fabrics in Agriculture. Non-woven textiles were first introduced to agriculture in Europe in 1978. They are used to keep the carrots warm in the beginning of harvesting, and to protect against whiteflies as well as tomato leaf viruses. Non-woven fabrics in the United States are used for mulching sweet peppers, cantaloupes, tomatoes and root vegetables. It is used mainly to keep heat in check, as well as early harvesting and insect control. Non-wovens are a great way to cover mats that are grass-proof and increase soil temperature. To ensure that roots completely absorb water, the short fibers can also be used to make blankets that absorb water. They can be used to make turf or as lawns for gardens. They are also used as planters for large woody plants such as garden trees and fruit trees, preventing weeds and retaining the moisture. Non-woven fabrics are commonly utilized in Taiwan as crop covers. Non-woven fabric is extensively used in greenhouses of large size for energy conservation and environmental control. Double-layered cover and canopy curtains cut down on heat radiation and solar radiation during the night. To shade and protect the bulbs of cauliflower, high-density, non-woven spun-bonded TAVIK fabrics were employed. Farmers quickly adopted it due to its excellent shading ability, low thermal conductivity, easy recyclability and easy acceptance. Later, it was used for the preservation of leaf vegetables and insect-proof cultivation. Later, it was used for shading, heating, and protect fruit trees and pineapples. The development of non-woven industries has been slow due to Taiwan's unique ecology and climate. Non-woven fabric makers in Taiwan continue to work on developing non-woven technologies. They are focusing on the absorption of water and air permeability of non-woven fabrics. To use it in the preservation and storage of agricultural goods, it has strengthened its research and hopes to broaden the scope of applications. Look at this pp agricultural nonwoven fabric for advice.